Automatic Lubrication Systems

Automatic Lubrication and/or Grease systems are vital for the on-going maintenance of any type of machinery. You are ensured that each lubrication point gets the correct amount of grease, in small doses and regular intervals while the machine operating. At Powaforce we supply / fit / repair and maintain these systems on machinery with the best quality products.

With a wide variety of lubrication products, Powaforce are able to quote and attend to any type of automatic lubrication systems installation and breakdown services required by clients from Cape Town, Western Cape to the borders of South Africa. We supply most brands, such as Lincoln Lubrication Systems, Dropsa Lubrication Systems, Groeneveld Lubrication Systems and Beka-Max Lubrication Systems. Powaforce Engineering Solutions has the knowledge and experience to assure our clients that they will receive the best possible prices on all lubrication products and services. Our wide range of products allow us to give comprehensive solutions on all lubrication systems and replacement parts required for various industries such as Industrial, Automotive, Food and Beverages, Mining, Marine, Construction and Transport Insustries.

Types of Automatic Lubrication Systems

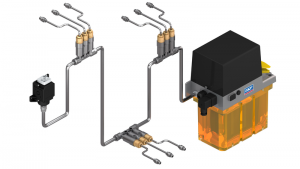

Single Line Lubrication Systems

A Single Line Lubrication System consists of a central pump station that automatically delivers lubricant through a single supply line to the lubricant metering device/s or Lubrication Injectors (for heavy duty equipment). Each metering device or Injector serves only one lubrication point and may be adjusted to deliver sufficient amount of grease or oil required.

Advantages of Single Line Lubrication Systems:

- Easy to install and Maintain.

- Available in both preset and adjustable models.

- Suitable for almost all lubricants.

- Easy system expansion.

- System continues to operate even if one point becomes blocked.

- Integrated system control and monitoring.

- Able to pump long distances and within a wide

temperature range. - Eliminate the risks associated with manually lubricating hard-to-reach areas.

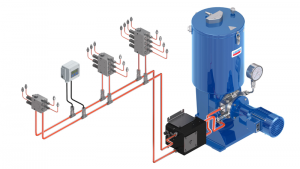

Dual Line Lubrication Systems

A Dual Line Lubrication System consists of a central pump station that automatically delivers lubricant through two supply lines to the lubrication metering device/s or lubrication Injectors, with both of them actuated alternately by means of a changeover valve once the preset pressure has been reached. A lubrication cycle is completed when both main lines have to be alternately pressurized and be relieved of pressure.

Advantages of Dual Line Lubrication Systems:

- Easy to install and Maintain.

- Available in both preset and adjustable models.

- Suitable for almost all lubricants.

- Easy system expansion.

- System continues to operate even if one point becomes blocked.

- Integrated system control and monitoring.

- Able to pump long distances and within a wide

temperature range. - Eliminate the risks associated with manually lubricating hard-to-reach areas.

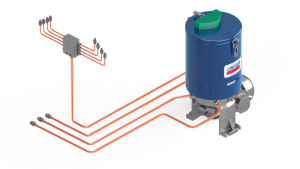

Progressive Lubrication Systems

Progressive Lubrication Systems provide continuous lubrication as long as the pump is in operation. Once the pump stops, the pistons of the progressive metering device or distribution block will stop in their current positions. When the pump starts supplying lubricant again, the pistons will carry on where they left. Therefore, the progressive cycle of one outlet of the pump will stop when only one lubrication point is blocked. The blockage serves as a means of control and forces personnel to service the system.

Advantages of Progressive Lubrication Systems:

- Continuous lubrication – Delivers frequent and measured amounts of lubricant to each lubrication point.

- Reliable monitoring and control – Easy system monitoring and simple blockage control, integrated system control and monitoring.

- Effective in harsh conditions – Potentially high lubrication point back pressure, dirty, wet or humid environments and low temperatures.

- Eliminate the risks associated with manually lubricating hard-to-reach areas.

- Reduced Equipment Downtime.

- Reduced Equipment Maintenance Cost.

Single Point Lubricators

A Single Point Lubricator is designed to automatically supply a small quantity of clean grease or oil to a single lubrication point on a regular basis, improving bearing performance. Single Point Lubricators are suitable for a variety of applications but often are used on pumps, electric motors, fans, blowers, conveyors and chains.

Advantages of Single Point Lubricators:

- Easy to install and Maintain.

- Eliminate the risks associated with manually lubricating hard-to-reach areas.

- Reduced Equipment Downtime.

- Reduced Equipment Maintenance Cost.

Why Choose Us

Over 10 Years

System Designing

Short/Long Term Savings

24/7

Workmanship

Products

Get in Contact!!!

You may also like…